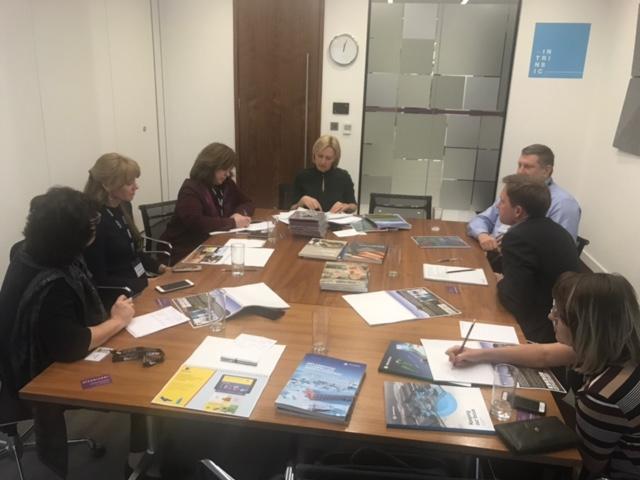

13-18 November 2022. A group of senior managers and mining engineers from leading Eurasian mining companies attended a program of site visits in Chile focused on operation of automated and robotics machinery and equipment in Chilean mines. The group visited Tres Valles underground and open-pit mines, El Teniente, the largest underground copper mine of CODELCO, Cerro Negro Norte iron ore open-pit production and BHP Escondida mine remote operations control centre.

On the Photo: CerroNegroNorte Open-Pit Mine

The program of the visit was supported by leading Chilean technology and consulting company REDCO, specialists in digital mine planning, geomechanical modelling, audit of geotechnical structures and mine design.

The group visited Cerro Negro Norte mine located in Chile’s northern Atacama region, 32 km north of Copiapó. This is one of the most innovative and environmentally friendly mining complexes in the country with a focus on sustainable development. The mine is owned and operated by Pacific Mining Company, part of the CAP group. Current production is 4 million tons of pellet feed (iron concentrate) per year, which is transported in the form of pulp via an 82-kilometer-long concentrate pipeline to the Puerto Punta Totoralillo facilities. From there the cargo is shipped to its final destination.

The highlight of the programme was a site visit to the world’s largest underground copper mine, El Teniente, the largest operation by CODELCO. According to experts El Teniente is one of the most advanced automated underground mines in the world.

.

Since 2011 a $3.4 billion new production level has been developed and operated to extend the life of the mine by another 50 years. The main objective of the project is to switch to an underground operation of exclusively remotely controlled robotics equipment.

The group visited Minera Tres Valles copper mining complex – Don Gabriel open pit and Papomono underground mines.

Minera Tres Valles is a medium-sized copper mine owned by the Canadian company Three Valle Cooper. The mine produces high-quality class A copper cathodes, which was achieved by processing ore from our Tres Valles mines, as well as ore purchased from local small miners. The mining operations of the company are located in the valleys of Chalinga, Carcamo and Chuchini, near the cities of Salamanca and Ilhapel in the southern part of the Coquimbo region. Minera Tres Valles is a private copper producer with 100% ownership of the Minera Tres Valles operating copper complex.

The complex has significant infrastructure, including a processing plant with a capacity of 5,400 tons of ore per day. The plant has a copper leach line that includes a four-stage crusher, sinter plant, heap leach pads and ponds, and an SX-EW electrolysis plant with an annual capacity of 18,500 tons of copper cathodes.

Some facts of Minera Tres Valles:

• Vale has invested over US$240 million into the site

• Crushing capacity up to 7000 t/day

• Chloride (salt) leaching infrastructure added in 2020.

• Strong local community support and partnerships with small local miners.

Volume and methods of extraction. The Don Gabriel open pit plan 852,000 t/y of ore, which equates to 2,400 t/d for 365 days a year. The Papomono Masivo underground facility uses a combination of front-end caving and block caving methods

During the site visit to Tres Valles mine visitors discussed mine planning, design and transition from open pit operation to underground mining.

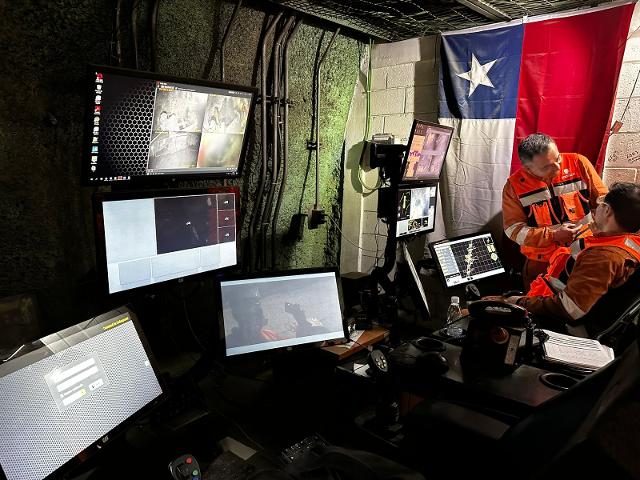

Mining companies from Kazakhstan also visited BHP’s Minera Escondida remote control centre in Santiago de Chile. While touring the centre and getting to know the management of the mine, there was a lively discussion between the visitors and BHP engineers on automation and remote control of equipment operating at one of the largest open pit copper production.

Minera Escondida is a mining company that owns two open-pit copper mines in the Atacama Desert, 170 kilometers southeast of Antofagasta in northern Chile, at an altitude of 3,050 meters above sea level. It is currently the most productive copper mine in the world. In 2020 the mine produced 1,185 Mt of metal, primarily copper concentrate, and a small proportion of copper cathode. This is obtained as a result of leaching of both oxide and low-grade sulfide ores. The mine also produces gold and silver. According to the available data, this represented 9.5% of world production and 26% of Chile’s production.

Copper concentrate from Escondida mine is transported as a slurry via pipeline to the port of Coloso where it is dehydrated before being exported.

The mine started operation in late 1990s and has since increased throughput through phased expansions over the years. The third line for the production of copper concentrate with a capacity of 152,000 tons per day was commissioned in 2016. The plant increased its total copper processing capacity to more than 422,000 tons per day. The mine currently features three concentrators and two leach units (oxide and sulfide).

The ore is transported to two semi-mobile in-pit crushers for primary crushing prior to transport to the coarse ore stockpile. The stripping ratio is estimated to average around 1.7:1 over the life of the project. Mining trucks are dispatched and monitored by Wenco International Mining Systems and costs are managed by Mincom Mine Information Management System.

The Transeuropean Centre would like to expresses special gratitude to Olesya Dashavskaya and Enrique Rubio of REDCO, as well as all personnel and management of BHP, Minera Tres Valles and CODELCO for organizing and facilitating this interesting visit to Chile.